Grinding Spindles

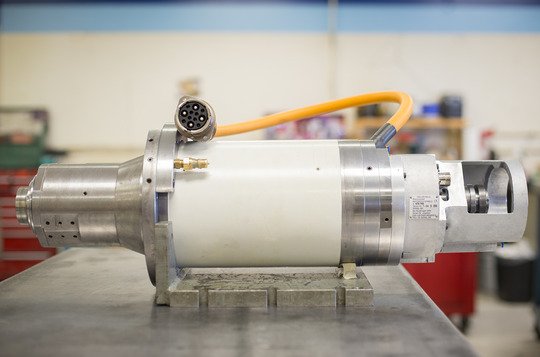

Work-head Spindles – Inbuilt & Belt Driven

Work-head spindles, both inbuilt and belt-driven, are essential for precision machining. They ensure accurate rotation and stability, enhancing the quality and efficiency of mechanical engineering processes.

- Precision rotation for high-quality machining.

- Enhanced stability reduces vibrations.

- Versatile for various mechanical engineering tasks.

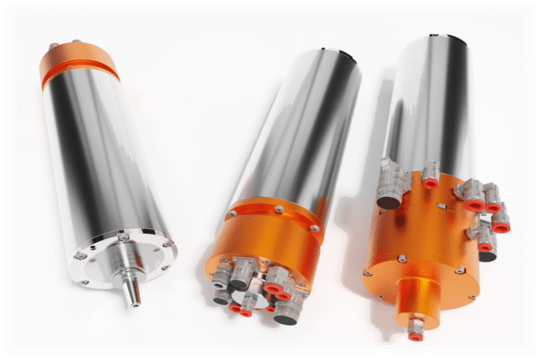

External Grinding Spindle

External grinding spindles provide precise rotation and stability, essential for achieving high-quality surface finishes in grinding operations. They enhance machining accuracy and efficiency in various industrial applications.

- Ensures precise rotation for high-quality surface finishes.

- Enhances machining accuracy and efficiency.

- Ideal for various industrial grinding applications.

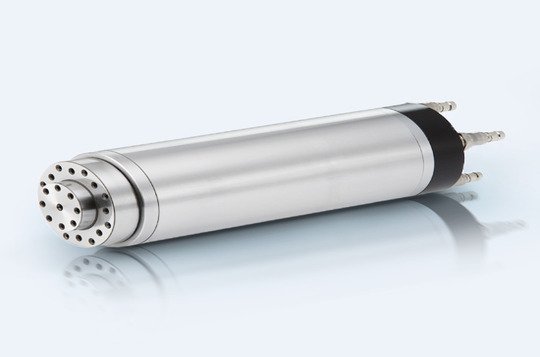

Internal Grinding Spindles

Internal grinding spindles offer precise and stable rotation, essential for achieving high-quality internal surfaces. They enhance the accuracy and efficiency of grinding operations in various industrial applications.

- Provides precise and stable rotation.

- Ensures high-quality internal surface finishes.

- Enhances accuracy and efficiency in grinding operations.

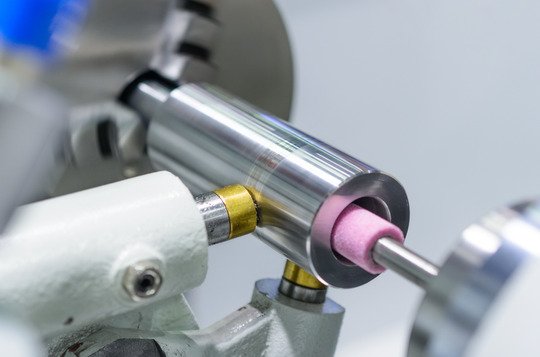

Dressing Spindle

Dressing spindles ensure precise tool sharpening and maintenance, essential for optimal grinding performance. They enhance the accuracy and efficiency of grinding operations, extending the life of grinding wheels.

- Ensures precise tool sharpening and maintenance.

- Enhances accuracy and efficiency in grinding.

- Extends the life of grinding wheels.

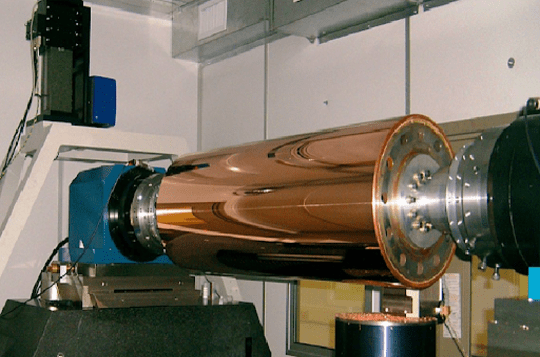

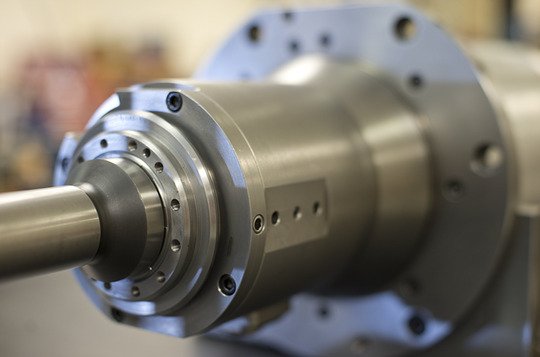

Hydrostatic Spindle

A hydrostatic spindle utilizes fluid pressure to support the rotating shaft, providing exceptional stability and vibration reduction. This design enhances machining precision and longevity, ideal for high-precision manufacturing applications.

- Utilizes fluid pressure for exceptional stability.

- Reduces vibrations during operation.

- Ideal for high-precision manufacturing applications.

Aerostatic Spindle

An aerostatic spindle uses compressed air to create a thin film of air between the spindle and its housing, ensuring ultra-precise and stable rotation. It's crucial for high-precision machining applications.

- Utilizes compressed air for stable, precise rotation.

- Creates a thin air film for reduced friction and vibration.

- Essential for high-precision machining tasks.

Customize Spindle Solution – Flexible as per Customer requirement.

Our customized spindle solutions are tailored to meet specific customer requirements, offering flexibility in design, functionality, and performance. We ensure precise engineering to enhance productivity and meet diverse industrial needs effectively.

- Tailored to meet specific customer requirements.

- Offers flexibility in design and functionality.

- Engineered for enhanced productivity and diverse industrial needs.

Spindle Repair and performance enhancement.

Spindle repair and performance enhancement services restore functionality and optimize efficiency, ensuring reliable operation. We specialize in diagnosing issues, providing expert repairs, and implementing upgrades to extend spindle lifespan and improve productivity.

- Expert diagnosis and repair for spindle functionality.

- Performance enhancement through upgrades and optimizations.

- Extends spindle lifespan and boosts productivity.